Gear Hobbing Cutters: How to Select the Right Option?

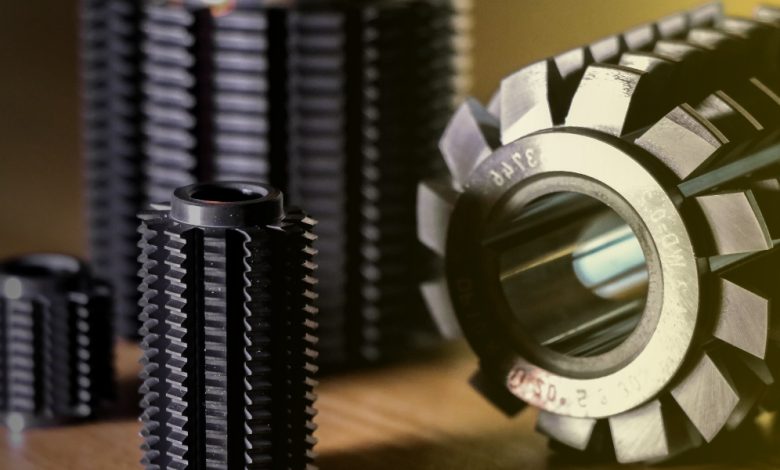

You know what, gear cutters and hobs are important tools for machining gear-tooth profiles. They are specific ground to produce teeth. Mostly of an involute form, in standard American pitches or that of even metric modules. Specialty or custom gear hobs are actually frequently available from professional gear hob suppliers.

You can speak with the and ensure that you get the type of tools that you require for your specific tasks. What you should understand is that these gear cutters and hobs could be of solid construction, or that of even with holders and inserts.

They can get used with a number of end or tip geometry options, encompassing square end, ball nose, that of radius tip, and chamfer tip. Then these square end tip geometry for gear cutters and that of hobs have a square or even straight end that includes no radius, chamfer, or that of other finish.

Speaking of ball nose gear cutters and hobs tips. They have a ball nose whose radius is that of one half of the cutter diameter. This kind of gear cutters and hobs tip is effective for machining female semicircular grooves of radii.

Similarly other ends as well as tips for gear cutters and hobs encompass radius or chamfer-tipped. Radius-tipped gear cutters as well as hob ends are straight flutes having ground radius on the very tip. Chamfer tip ends include an angled section of the side or even end. These tips form an angled cut of chamfered edge on a specific workpiece.

What to consider?

Once selecting a gear cutters and hobs, make sure that you give consideration to the desired finish type. There are characteristically two finish options: roughing or hogging and finishing. Roughing and hogging mills are specifically designed so that the machine geometry. Flutes, and even that of overall materials can get used for rapid and heavy material removal.

Similarly, remember that these are typically used to machine workpieces near to the desired finishing dimensions, where a finishing gear cutter and that of hobs takes over and generates closer tolerances and that of higher-quality surface finish.

Similarly, some other considerations for gear cutters and hobs encompass cutter size and that of construction criteria. Size considerations for them relate to the cutting diameter, shank or that of Arbor diameter. Flute or cutting-edge dimension, overall tool length, and even radius dimension and angle once applicable.

You know construction options for gear cutters and hobs encompass the number of flutes of cutting edges. This number is something that can vary with the cutter diameter, that of milling material, and other factors. Similarly, people use two-flute gear cutters and hobs with ductile materials that form up to produce long chips. Gear cutters and hobs making use of higher-number of flutes can get used to minimize chip load as well as vibration.

Conclusion

To sum up, no matter or any other type of cutters, if you keep the discussed considerations in mind , you can be happier with what you purchase.