How To Get Started with Acrylic Lasercutting

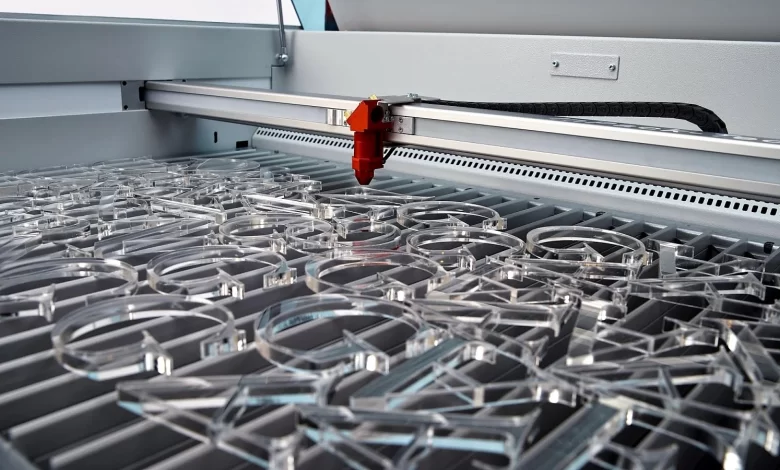

Acrylic lasercutting is a popular craze right now and the perfect DIY project to try. Acrylic Lasercutting creates detailed, intricate designs that are made possible by etching through thick acrylic sheets with laser blades.

This technique is an excellent way to create wall art at home without any prior experience!

What is Acrylic Lasercutting?

Acrylic lasercutting is a type of 3D printing that uses a laser to cut pieces out of a material like plastic or acrylic. It’s an affordable way to create custom parts and products, and it can be used with a variety of materials.

How to set up an Acrylic lasercutting machine?

Lasercutting is a great way to add detail, shape, and beauty to your acrylic projects. Here are the basics on how to set up your laser cutter and get started creating amazing pieces with this cutting technology.

First, you’ll need to make sure that your lasercutter is properly set up. There are a few different parts that need to be calibrated and aligned correctly in order for the machine to produce accurate cuts.

You can find instructions online or ask your local laser supplier for help.

Once your machine is calibrated, it’s time to load your material into the feeder. You’ll want to use a standard 8mm thickness of acrylic sheeting. Make sure that the material is stretched evenly across the entire width of the sheet so that it doesn’t curl during the cut process.

Next, start by positioning the material over the top of the Expo-Lap plate and ensure that it’s flush against the edge of the plate.

Screw down the hinged side panel firmly onto your printer bed so that no air bubbles form during printing (this will prevent issues with registration). Finally, secure your material in place with clamps or weights if necessary.

Tips for Cutting

1. Start with high-quality acrylic. If the acrylic is not of good quality, the results will not be satisfactory.

2. Work in a well-lit area to avoid shadows and uneven cuts.

3. Keep your hands clean and dry to avoid friction and heat-caused oxidation.

4. Use a mounting board or other support to hold the acrylic in place while lasering.

5. Adjust the laser power and speed to achieve the desired results.

Setting Up Your Own Shops

If you’re interested in starting your own acrylic lasercutting business, there are a few things you’ll need to get started.

First, you’ll need to purchase a lasercutter. There are a number of options available, so finding the right one for your business is important.

You’ll also need an acrylic sheet material, and software to help you create your designs. Finally, you’ll need to set up your shop and marketing strategy.

When choosing a laser cutter, make sure it has the features that will best meet your needs as a business owner.

For example, look for a machine that has multiple cutting depths and speeds, so you can create precise cuts without having to redo them often.

Additionally, make sure the machine has easy-to-use controls so you can quickly create your design.

Acrylic sheets are another essential part of starting an acrylic lasercutting business. You’ll need to purchase at least one sheet of material per design project you wish to produce.

Acrylic sheets come in various sizes and shapes, so be sure to select the correct size for the project you’re working on. Once you have purchased your sheet material, it’s time to start creating your designs!

One of the most important aspects of setting up an acrylic lasercutting business is developing a marketing strategy. This will include identifying target markets and developing creative ways to reach them.

Additionally, it’s important to establish pricing policies and develop customer relationships from

Conclusion

Acrylic lasercutting is a fantastic way to add detail and dimension to your projects. In this article, we will walk you through the basics of acrylic lasercutting so that you can get started creating amazing pieces of art with this innovative technology.

If you’re interested in learning more about how acrylic lasercutting works and finding out some tips for getting the most out of your cuts, be sure to read on!